APRILE 2023 PAG. 21 - The Padua Interport Platform for Intermodal and Logistics

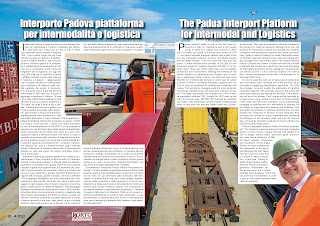

Padua Interport today is one of the first three inter-ports in Italy for importance and is the largest by far in sales 35.7 million euro turnover in 2022 with 2.8 million euro profit. It is at the core junction of TEN - T. the trans-European transport network and is part of the two new European transport corridors, the Mediterranean and the Baltic Adriatic. Over the years the Inter-port has grown. Current infra-structure consists of 520,000 m² and numerous stores for logistics covering 300,000 m² of covered area. These are rented rather than sold to logistics companies and transporters, enabling the meeting of the double objective of capitalising the company and of creating a guaranteed rental income. The inter-port also owns 300,000 m² of Intermodal terminal to which can be added a further 70,000 m² owned by Mercitalia Logistica with 18, 750 mt long rail platforms for loading and unloading with cranes. The terminal is managed using the most advanced technology available today with automatic road and rail gates. The digital procedures are controlled by a new in-house developed software TOS. Results for 2022 were in line with the previous year, 365,000 TEU handled by container and trailer in the Intermodal terminal thanks to 8000 goods trains to and from the principal Italian ports and European terminals. This year is expected to show an increase in the demand for road/ rail transport, although up to now, the demand for intermodal road/rail was basically for maritime containers with connections between land ports and terminals. Today’s market is looking for trailer intermodal between Northern Italy and Central Europe. Inter-port Padua already manages two multi-weekly trains with trailers between Padua, Cologne and Geleen. A further two services will start in the next few months as a result of a new park with space for 200 trailers positioned where loading and unloading can use electric cranes. In 2023 Inter-port Padua will continue the in house development of the new TOS software for intermodal traffic flows.

In order to make the best use of resources of vehicle time and of stocking. Each individual unit in the terminal will be controlled by applying sophisticated algorithms . By 2024 this strategic move will enable the automation of handling containers together with automatic trains for the trucks and trains both entering and leaving the terminal. The automation will be in two phases. First, cranes will be operated by a crane driver using remote control and not being present in the cabin and then each operation will be automatically managed by software and the intervention of operator will be limited to supervision and dealing with problems. This will enable the software to optimise handling time, but also position the containers in function of their need/use, thus reducing the number of empty containers and increasing the efficiency of the terminal, which will work 24 hours a day, powered by electricity produced in-house with the new innovative photovoltaic plant.

Franco Pasqualetti Interport Padua President commented. “Our objective is always looking to the future of logistics thanks to inter-modular using a terminal with platforms of 750 mt length, electric trains, automatic gates, photovoltaic roofs and a distributor of GNL for heavy vehicles. Procedures and operations will be digital. Shortly we shall complete the full automation of the terminal becoming the first Italian inter-port and one of the first in Europe to adopt automation of this type. Putting together these factors makes Interport Padua a business genuinely sustainable for the environment and a fundamentally sane business, which makes profit and reinvestment in order to give an ever better service to international operators.

.gif

)

.jpg)